How Beekeepers are Using Galvanized Wire Mesh

Wire Mesh is Saving the World: Find Out How

Beekeepers, architects, and pharmaceutical scientists are all using wire mesh in their work to create progress in our everyday lives. Wire mesh, also known as wire cloth, is a fabric-like material used in a variety of applications. A material this versatile and customizable can be used in different industries that are furthering our progress in sustainable and environmental practices. Read this article to find out more about how woven wire mesh is helping save the world.

How Beekeepers are Using Galvanized Wire Mesh

Wire cloth is a common material used in the beekeeping world. Galvanized wire mesh is used by many beekeepers to create hive ventilation while keeping out potentially harmful bee enemies, like the Varroa mite. Galvanized steel mesh is beneficial due to the galvanized coating which prevents water and other corrosive elements from interacting with the steel. The galvanization acts as a great shield for steel, as well as iron, which is also highly vulnerable to rusting. Outfitting the hive with specialty wire cloth creates a safe and protective environment for the bees to continue to produce honey for the masses. A small opening in the wire cloth used can also assist in cleaning the pollen off of the bee’s legs when they pass in and out of the opening. Adding a layer of welded wire mesh to the bottom of the structure can also add a layer of protection from mouse access.

How is this saving the world? It’s all about the bees! Almost 90% of plant species rely on pollinators to reproduce. Meaning bees play a vital role in the environment and in the agriculture industry. In addition to their necessary work as pollinators, bees produce honey, beeswax, royal jelly, and propolis. Beekeepers or apiarists are assisting in providing bees with homes to help the humble pollinators stay safe and grow the bee population that has declined in recent years.

How Architects are Using Woven Wire Mesh

Bees aren’t the only ones benefiting from woven metal mesh. Architectural designs that utilize wire mesh as a building material are reducing environmental strain. Metal mesh is a frequently used material in architecture due to its lighter weight and flexible design. Despite its lighter weight, woven wire mesh is known for its durability and strength. The interwoven and clinched design of the mesh results in a durable material that retains its structural integrity during use even when subjected to impact and other stresses. The 316L stainless steel wire mesh alloy is often used for its benefits when it comes to avoiding corrosion.

Woven wire mesh offers decorative and functional support in many of the architectural applications that help in enhancing a project’s quality and controlling the costs. In using recyclable materials in construction and architectural design, sustainability goals can be met, requiring less of a need for new materials. Architectural woven and wire mesh applications include partitions, screens, wire railings, water feature fabrication, and more.

How Pharmaceutical Scientists are Using Wire Mesh

As efforts to reach a more sustainable and environmentally-friendly normal are at the forefront, so is the endeavor to better public health. Every day biologists and pharmaceutical scientists work to find miracle breakthroughs in modern medicine. These breakthroughs with medication and vaccines come with the help of wire mesh!

Nutsche filters are crucial in pharmaceutical and fine chemical research and development and production operations. Nutsche filtration is a batch filtration technique that uses vacuum or pressure in a closed vessel in combination with a wire mesh filter disc fitted with the appropriate filter to force liquid through the filter to form a solid bed. Five-layer sintered wire mesh laminate is ideal for the Nutsche filter process due to the filter medium having the ability to operate under a wide variety of temperatures and pressures while maintaining its opening size. Additionally, corrosion resistance and mechanical strength attributed to 5-layer sintered wire mesh are beneficial for this process.

Lawrence Sintered Metals Offers Mesh Materials to Help You Save the World

Whether you need a single metal mesh screen or require a bulk order to finish a commercial job, Lawrence Sintered Metals is here to help fulfill your wire mesh needs. Wire mesh is being used to save the world in a variety of ways but we’re here to offer wire mesh to save your world. Our wire mesh professionals can help you find the right product for your job. Contact Lawrence Sintered Metals today to learn more about the best-quality and budget-friendly sintered wire cloth offered in the industry.

HOW VERSATILE IS STAINLESS STEEL WELDED MESH?

What is Welded Mesh?

Stainless Steel Wire & Mesh (SSWM) are Australia’s largest stockist of stainless steel wire and mesh. SSWM stocks two forms of welded mesh:

- Stainless Steel Welded Panels

- Stainless Steel Welded Rolls

They are manufactured by longitudinal and transverse wires being resistant welded together. As the wires are welded at each intersection, it gives the mesh additional strength and improves the capability of maintaining its integrity under stress.

What are the benefits of stainless steel welded mesh?

Stainless steel welded mesh plays a key role in modern day society, with endless applications. It is incredibly durable and non-corrosive, providing long-term performance with minimal maintenance.

Benefits include:

- Corrosion resistant

- Strength

- Minimal maintenance

- Low life cycle costing

- Endless recyclability

- Aesthetic appeal

- Hygienic properties

Welded Panels Vs Welded Rolls?

The main difference between welded panels and welded rolls is the size of the wire diameter. Welded panels have a larger diameter and are therefore more suitable for projects that require more strength. Welded rolls have a smaller wire diameter and would be more suitable for projects that require more flexibility of the welded mesh.

To select the most appropriate product for your project, it is important to know and understand your application and environment. The product that best meets your needs, is determined by its mechanical and chemical properties and finishes.

Stainless Steel Welded Panels:

SSWM stock an extensive range of welded mesh panels, with a width of 1200mm and a length of 2400mm. The welded panels have the edges trimmed (flush).

Common applications:

- Constructional material for bird aviaries

- Reinforcing material for bridges, tunnels, piers, docks, sea walls and structures in splash zones

- Protection guards for machinery and automated equipment

- Anti-climb security mesh for fences

- Gabion mesh for retaining walls

- Green walls for architectural designs

SSWM also stock an extensive range of welded mesh rolls, with various widths and a length of 30m. The wire diameter starts at 0.8mm to 2.5mm and the mesh from 6.35mm to 50.8mm.

Common applications:

- Constructional material for zoological enclosures

- Bird-Proofing for buildings

- Building Protection from Vermin and Rodents

- Safety mesh for Roofs

What is stainless steel?

Stainless steel is classified by its crystalline structure in three categories: austenitic, ferritic, and martensitic. Austenitic stainless steel has nickel added so the crystalline structure changes to austenite. The basic composition of austenitic stainless steel is 18% chromium and 8% nickel. Grades 304 & 316 are both austenitic stainless steels and are stocked at SSWM.

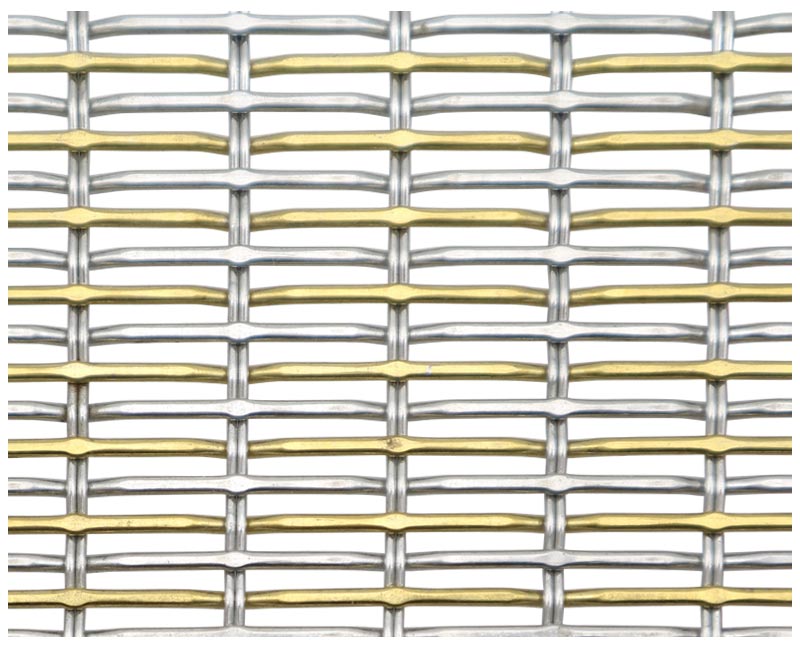

Woven Wire Mesh:

|

| source: www.bzwiremesh.com |

What is the difference between Grades 304 & 316?

Grade 316 has a higher resistance to corrosion and sea water due to the addition of molybdenum to its chemical composition. Grade 304 has a chemical composition of 18-20% Chromium and 8-10.5% Nickel and Grade 316 has a chemical composition of 16-18% Chromium, 10-14% Nickel and 2-3% Molybdenum. Grade 304 has a higher melting point and can withstand higher temperatures than Grade 316.

Technical Information to make selection and specification easy:

Our clear and easy to follow technical information will assist you as follows:

Stock guide

SSWM have developed a product selection guide to assist you with selecting the most appropriate welded mesh for your application. It is a great visual resource.

Technical Data Sheets

Contains all the information you require for specifying and ordering.

评论

发表评论